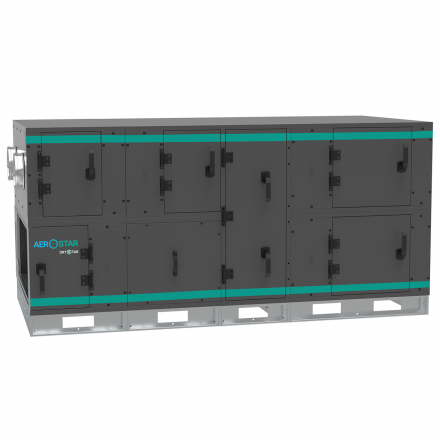

DRYSTAR

Capacity

1 000 – 8 000 m³/hour

Area of usage:

- ice arenas, food industry, pharmacy, warehouses, museums, medicine.

Can be used both independently (indoors or outdoors), and in a complex with air-processing

system.

- Dehumidifiers reduce humidity without changing the temperature.

- Support the creation of normatively necessary conditions for people who are indoors.

- Control and maintain the required relative humidity for production technology in industrial buildings.

- Protect from corrosion, provide electrical and environmental safety.

- Reduce the humidity level to remove the load and increase the service life of refrigeration units.

- The air is dried, preventing the formation of ice in refrigerators and freezers, transitional vestibules.

- Intensively remove moisture after natural disasters, floods or waterfloods.

- Dry the objects during building on the stages of finishing, concrete or repair works.

- Remove the evaporations from the pool mirrors, preventing formation and dropout of condensate on equipment and surfaces.

- Carry out dehumidification during complex air treatment.

*Optionally: the unit can be equipped with sensors of air moisture.

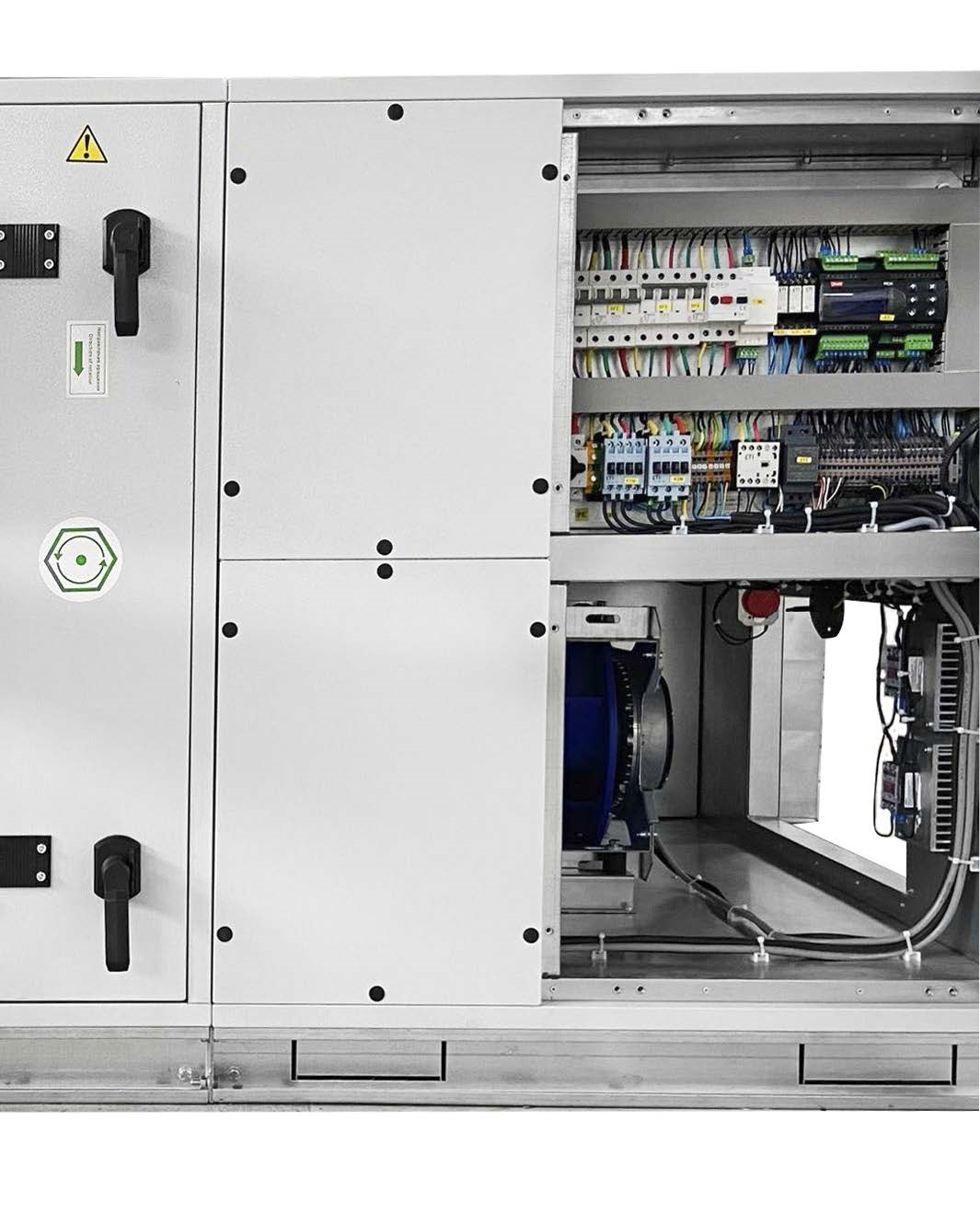

Basic configuration

Pocket filer

The pocket design guarantees the increase of filtration area and provides maximum efficiency. Made of a durable painted metal frame.

Filter material: polyester / micro-fibreglass.

Filtration class acc. to ISO 16890: Coarse. ePM10. ePM2.5. ePM1

Working environment temperature: up to 80°C.

Humidity of the working environment: ≤100%.

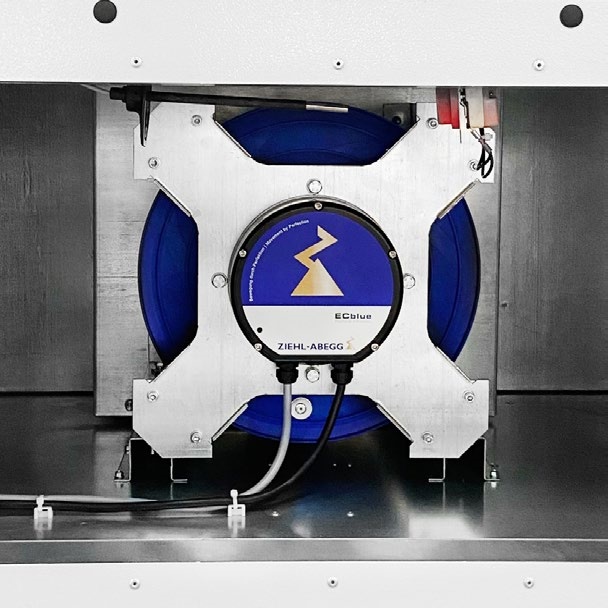

EC-motor

Brushless synchronous motor with electronic control highly reduces noise level.

High working pressure: up to 2500 Pa.

Wide range of nominal voltage: 200-277V and 380-480 V ±15%.

Long service life: more than 80000 hours of continuous work.

EC-electric motor with efficiency higher 90%

• Saves at least 30% more electricity than an AC motor.

• Complies with the ErP 2015 directive.

• Built-in EMC filter protects against phase loss and low voltage in the network.

• Protection against overheating of the motor and electronics, and protection against rotor lock.

• No starting currents.

• No service needed.

• The absence of the frequency converter saves installation space.

• Allows reduction of the fan capacity up to 10%.

• Optionally EC-motor is equipped with MODBUS RTU protocol.

Option. Application of the Flow Grid technology: air flow rectifier.

CONTROL

• dehumidification according to moisture sensor;

• dehumidification at the external signal from the automation system;

• automatic shutdown of the unit in case of emergencies or fire;

• automatic restart of the unit after a power failure;

• indication of operating modes of the unit;

• protection of motors and cables against short circuit;

• protection of fan motors and heaters from thermal overload.

SORPTION ROTOR

Adsorption dehumidifiers work at any temperatures and air humidity levels.

The rotor is the main element of the dehumidifier. Two isolated from each other air streams are passed through the rotor at the same time.

The first stream is dehumidified air.

The second stream is reactivation air.

Water molecules are absorbed by a special absorbent composition (based on silica gel) while passing through a rotary recuperator.

Moisture removal is accompanied by the air temperature increase.

While rotating recuperator enters the reactivation zone, where it is dried by a second stream of heated air. This way, its moisture-absorbing properties are restored.