GREENSTR

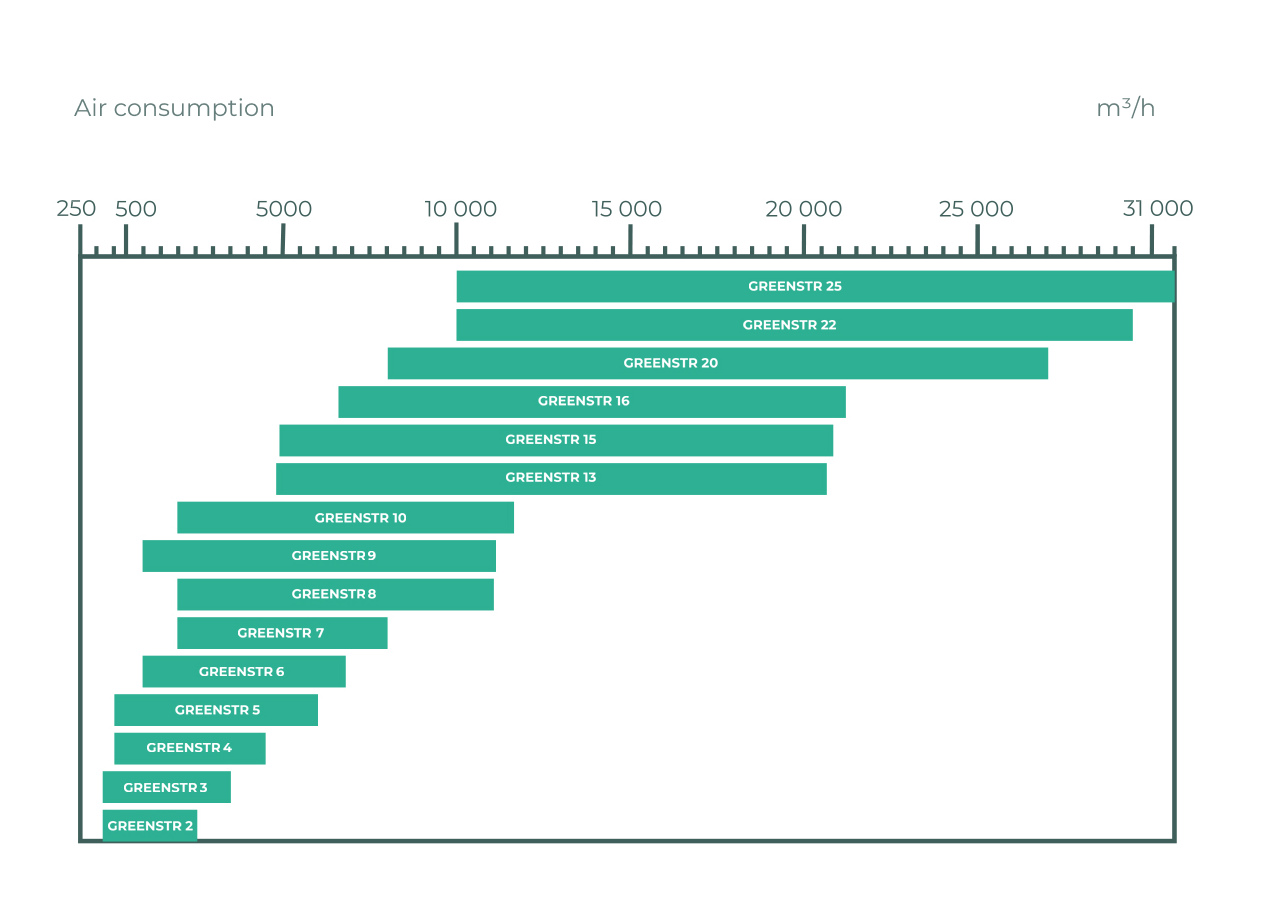

CAPACITY

From 250 m³/h up to 32 000m³/h

FEATURES

-

ENERGY-SAVING TECHNOLOGIES REDUCE THE PAYBACK PERIOD OF EQUIPMENT.

-

The units are equipped with a number of energy-saving technologies that allow users to gain the maximum efficiency at the minimum resource costs.

-

Automation is developed individually for each particular unit. Allows you to control the parameters of the equipment with maximum efficiency.

-

Medical modification of unit is possible.

-

Minimum manufacturing time of equipment.

ADDITIONAL OPTIONS

-

NON-STANDARD DESIGNING

Allows adaptation to any parameters and solve problems of different levels of engineering complexity.

-

PAINTING IN ANY COLOUR OF THE RAL PALETTE

-

POSSIBILITY OF INSTALLATION OF THE HEAT PUMP OF ANY LEVEL OF COMPLEXITY:

- Heating of supply air,

- cooling of supply air,

- heating / cooling of supply air by means of the energy-efficient heat pump working on ozone-safe freon R410a.

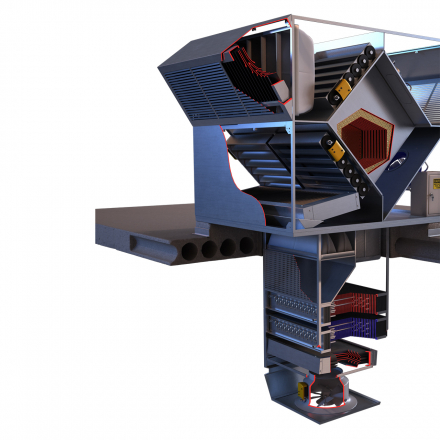

BASIC CONFIGURATION

CASE

Metal with a high content of zinc and extra-strong anti-corrosion coating allow you to install equipment inside and outside buildings of all types. (In case of outside installation the units are equipped with an air intake covers and protective deflectors. In this case air valves and automatic equipment are mounted inside.)

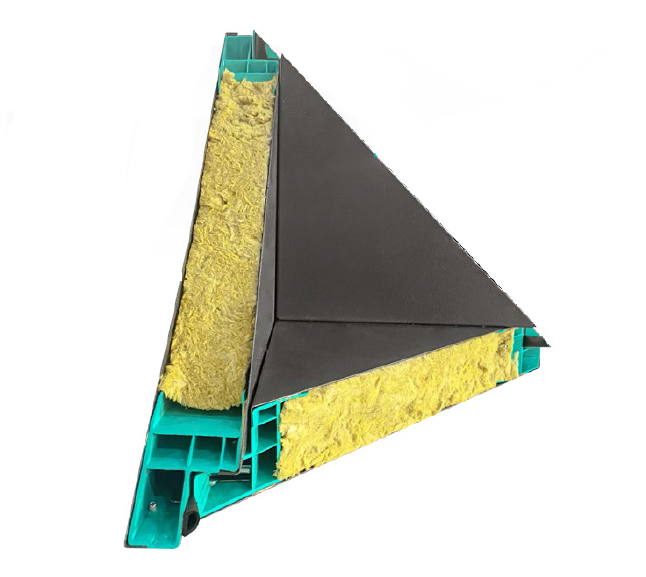

SANDWICH PANELS IN AN INNOVATIVE CASE made of PVC profile

Sandwich panels with thickness 50 mm made of rock wool with a density of 50 kg/m3 provide increased structural strength, heat and sound insulation.

-

Minimized heat bridges.

-

Valve of increased tightness (with a function of heating).

-

Minimal energy losses per square meter of surface.

-

PVC profiles are armed with a reinforced insert.

-

Powder epoxidized coating on the outside and inside surfaces of the case.

-

Simple and tight interconnection of sections.

-

Reduced weight of the unit.

-

Reduced production time.

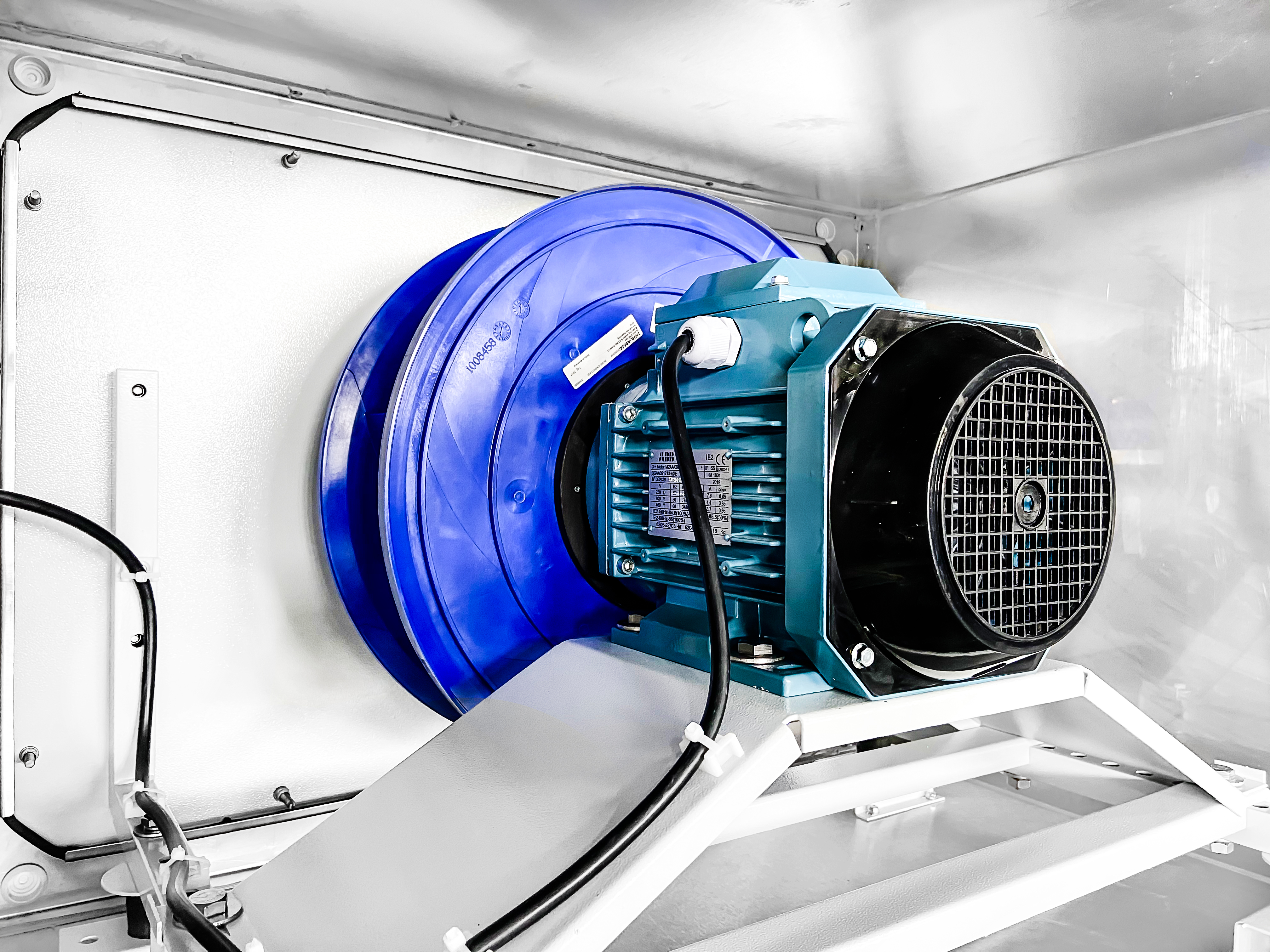

АС-MOTOR

Brushless synchronous motor with electronic control. The speed is adjusted depending on the required load which leads to significant energy savings compared to the usual cycle of cascade power on-off, as well as reduces noise level. It is placed on a vibration-resistant frame separated from the body of the unit. Perfectly adjusted to the aerodynamics of the ventilation network, it is possible to adjust the parameters if necessary.

ЕС-MOTOR

-

Energy efficiency classes: IE2, IE3.

-

Protection class: IP 55

-

Equipped with a frequency converter that enables quick reach the set point.

-

High working pressure: up to 2500 Pa.

-

Wide rated voltage range: 1 ~ 200..277V or 3 ~ 380..480V 50/60 Hz

-

Long service life: more than 80,000 hours

-

EC-MOTOR WITH EFFICIENCY ABOVE 90% saves at least 30% more electricity than an AC motor.

-

Complies with the ErP 2015 directive.

-

Built-in EMC filter protects against phase loss and low voltage in the network.

-

Protection against overheating of the motor and electronics, and protection against rotor lock.

-

No starting currents.

-

High working pressure: up to 2500 Pa.

-

Wide range of rated voltage: 1 ~ 200..277V or 3 ~ 380..480V 50/60 Hz

-

No service needed.

-

The absence of the frequency converter saves installation space.

-

Allows reduction of the rotation speed up to 10%.

-

Possibility of data exchange via MODBUS RTU protocol.

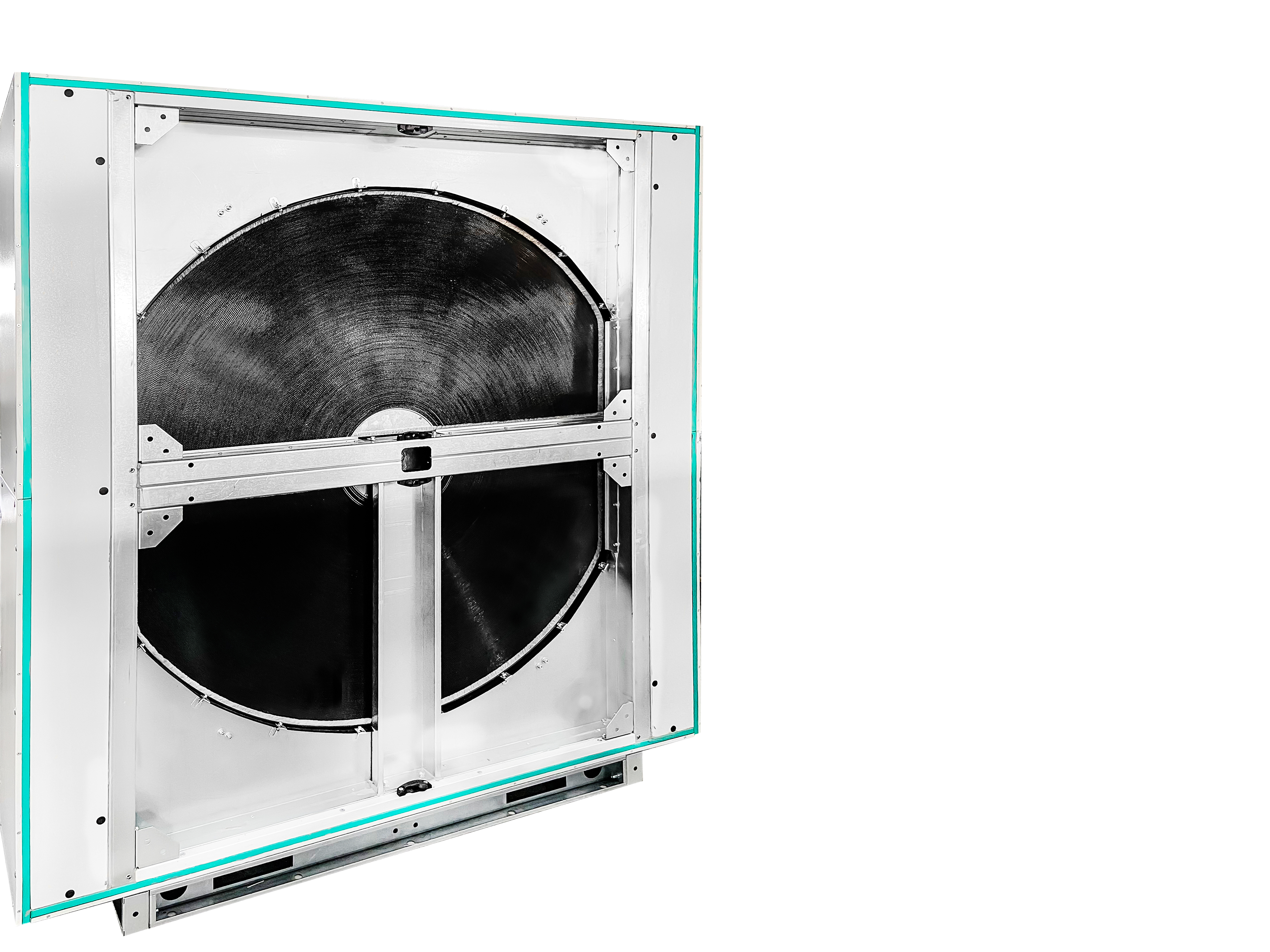

RECUPERATOR

The recuperation system allows reusing of the energy of the exhaust air from the room to heat and cool the air from the outside. The use of recuperator gives an opportunity to reduce the total energy consumption by 60%, which is especially important considering the rapid increases of energy prices.

Reduction of heat exchange areas and rotation speed at 10 rpm allows reducing energy consumption by 80%.

Moisture recovery depends on the temperature difference between the outside and exhaust air.

Equipped with a highly efficient brush seal.

- Foil thickness: from 1.4 to 1.8 mm.

- Height of foil waves: from 1.6 to 2.5 mm.

- Efficiency: up to 88%, depending on the size and operating parameters.

Electric drive with variable speed to maintain maximum efficiency and control the degree of energy utilization. Motor protection against overload.

CROSS-FLOW RECUPERATOR

Thanks to the plate heat exchangers, two air streams, for example, a warm exhaust air stream and a cold supply air stream pass next to each other, without any contact, on thin plates. Energy exchange occurs on the surface of the heat exchanger plates. At the same time there is no mixing of two air streams.

-

Efficiency: up to 85%, depending on the size and operating parameters.

-

Corrosion-resistant aluminium foil coated with epoxide resin.

-

Strong connection of plates thanks to double folding, pressure stability thanks to five-fold thickness of material.

-

Plate structure: embossed plates, distance between plates from 3.8 to 11.5 mm.

-

Air productivity: up to 25 000 m3/h.

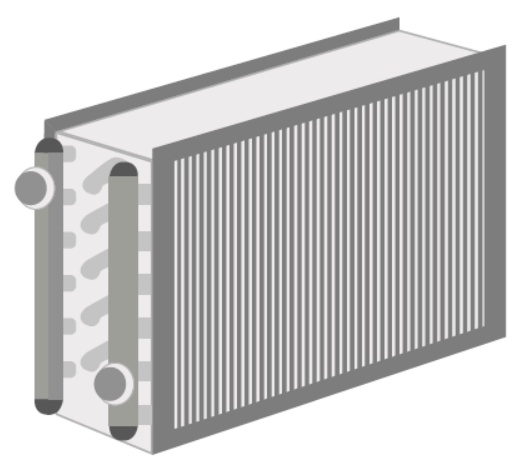

Glycol recuperator

-

It consists of two heat exchangers: one in the exhaust air flow, the other one in the supply air flow.

-

The main advantage of this recuperator is the possibility of its application in case of air flows location at a distance from each other;

Usage in systems where non-mixing of air streams is of high priority.

The heat exchanger located in a stream of exhaust air takes away thermal energy and transfers it to the heat exchanger mounted in a stream of supply air with the help of circulating thermal medium: a solution of water and glycol.

Efficiency of Glycol recuperator: up to 70%.

HEAT EXCHANGER

Suitable for thermal mediums of any types: freon, steam, water, glycol solution.

Basic configuration

Slat block:

- corrugated surface;

- internal notches, arranged in a chessboard order;

- number of tubes rows: 1-12;

- distance between the ribs: 1.6-5.0 mm;

- thickness of plates: 0,1-0,19 mm.

Heat exchangers range: up to 350 liters

Maximum working pressure: 20 atm. over.

Copper pipes: diameter - 9,52 mm,

wall thickness - 0.27 mm / 0.33 mm.

Collector made of copper or steel pipes.

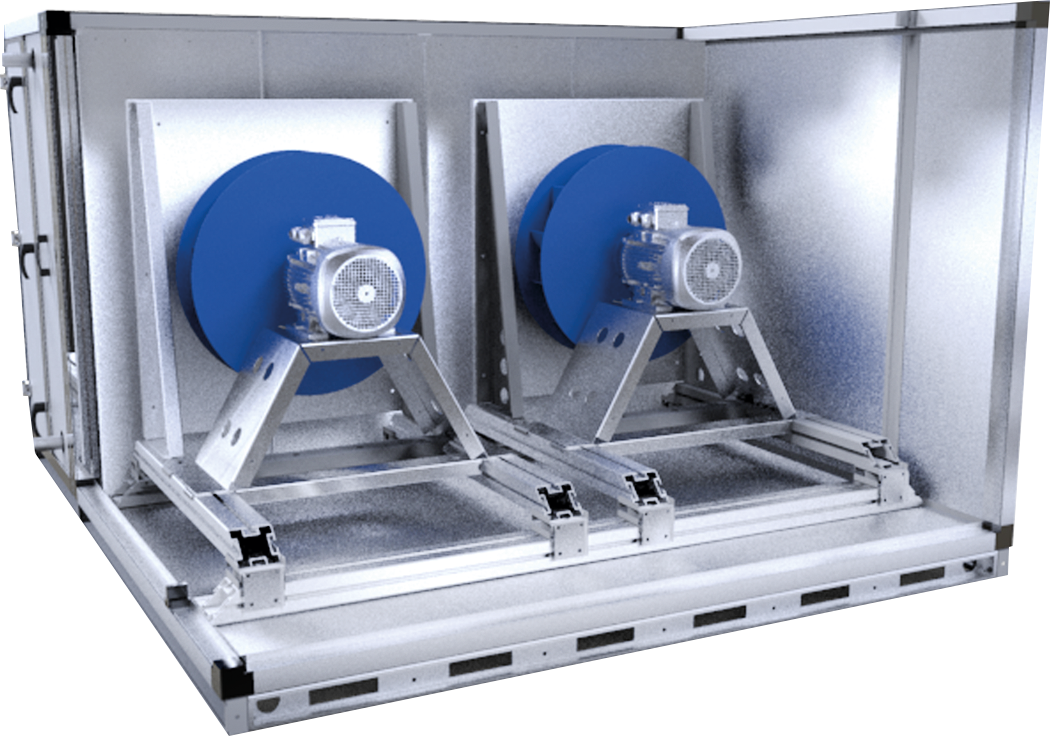

DUAL FAN

-

Dual fan system.

-

This configuration is 50% more reliable than a system with one powerful fan.

MODULAR FILTERS

Various filtration classes: from coarse to ultra-thin. Prevent migration of dust particles through the filter material. Cassette and pocket-type filters are used.

CASSETTE FILTER:

- Durable galvanized metal frame.

- The filter material is fixed on the mesh.

- Made of polyester fibres.

- Filtration class acc. to ISO 16890: oarse 70%, ePM10 60%, ePM2,5 75%

- Working environment temperature: up to 80°C.

- Humidity of the working environment: ≤100%.

POCKET FILTER

The pocket design guarantees the increase of filtration area and provides maximum efficiency.

Rigid construction of a strong painted metal frame.

- Filter material: polyester / micro-fibreglass.

- Filtration class acc. to ISO 16890: Сoarse 70%, ePM10 60%, ePM2,5 75%

- Working environment temperature: up to 80°C.

- Humidity of the working environment: ≤100%.